- November 9, 2023

- Category: CQV

As we are aware, projects are commonly divided into systems to facilitate construction management, document collation, turnover, and Commissioning and Qualification (C&Q) activities. System boundaries are marked on design drawings to clearly distinguish one system from another. This includes all components and piping, providing a logical definition of what is included and what is not included within each system.

It is crucial to define and document system boundaries early in the project, preferably during the Basis of Design (BOD) phase. This enables the development of a comprehensive systems list and allows for the subsequent execution of System Risk Assessments. The systems are typically listed in the C&Q Plan. System boundaries should be defined in a way that encompasses the entire project scope. This is typically documented in the system’s Process and Instrumentation Diagram (P&ID) or Process Flow Diagram (PFD).

One level down from the classification of systems is the classification of components within the system. Why do this? Two key reasons:

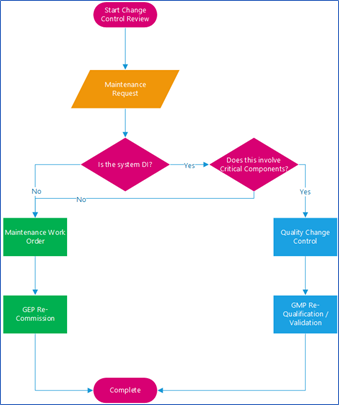

- The client needs to know which components are critical for calibration and other periodic preventative maintenance procedures. Otherwise, all components in a Direct Impact system must be classified as critical, creating more work and cost for no reason.

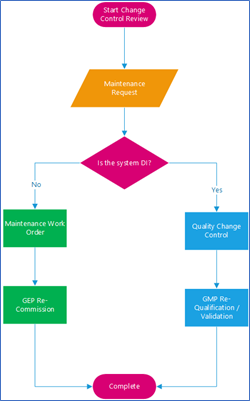

- During a work order, DI systems require Quality oversight in a formal change control process to avoid violating the qualified state of the system by replacing a component with one that has not been determined to be equivalent; or by not providing a re-qualification of the repaired or replaced component. If the component has been pre-determined not to be a critical component, then the change control can be signed off early in the process, saving time and cost.

The following diagrams illustrate this concept:

Component Classification – How To

Prior to the new ISPE C&Q Baseline Guide, most organizations that classified components did so via the CCA, or Component Classification Assessment. (For an example see, “ISPE Good Practice Guide: Approaches to Commissioning and Qualification of Pharmaceutical Water and Steam Systems (Second Edition) – APPENDIX 1 TYPICAL WFI GENERATION AND DISTRIBUTION SYSTEM COMPONENT CLASSIFICATION EXAMPLE”). This approach listed all the tagged components for a system and asked a series of yes/no questions that determined whether the component was GMP critical or not. The disadvantage of this was that, for systems with many components, it was a long process with many obvious “no” responses.

After the publication of the new ISPE C&Q Baseline Guide, 2nd edition in the summer of 2019, it was possible to quickly ascertain the critical components of systems since these were the CDEs or Critical Design Elements. This was determined by the SRA or System Risk Assessment. Since the SRA starts with the CPPs or Critical Process Parameters, it goes directly to what is critical. For example, if tank temperature is the only CPP, then we know that the temperature element in the tank is a critical component; there is no need to list all the other components and answer a series of questions for each one.

Summary

In the world of risk-based commissioning and qualification, the classification of components within systems is a game-changer for the client. As outlined here, this process is not only beneficial but essential for the efficient operation of the facility. Defining system boundaries early in a project, preferably during the Basis of Design phase, paves the way for a comprehensive systems list and facilitates System Risk Assessments. The classification of components within these systems serves two primary purposes: it identifies critical components for calibration and preventative maintenance, and it streamlines the change control process during work orders, saving both time and cost. The advent of the ISPE C&Q Baseline Guide, 2nd edition, has further simplified the identification of critical components, making the process more efficient and less time-consuming. This strategic approach to component classification is a testament to the evolution of risk-based C&Q, marking a significant step towards enhanced efficiency and cost-effectiveness.